-

17 June 2024

Psyllium Exporter

At Akash Agro Industries, we take immense pride in being a leading manufacturer and processor of organic and conventional psyllium seeds, husks, and powders. Founded in 1985, our company is dedicated to delivering the highest quality psyllium products to customers around the globe. Our state-of-the-art processing plant is equipped with fully automatic and ultra-modern machinery, ensuring the production of superior psyllium products in a clean and hygienic environment. In this blog, we will take you through our meticulous processing stages that transform raw psyllium seeds into premium products ready for export.

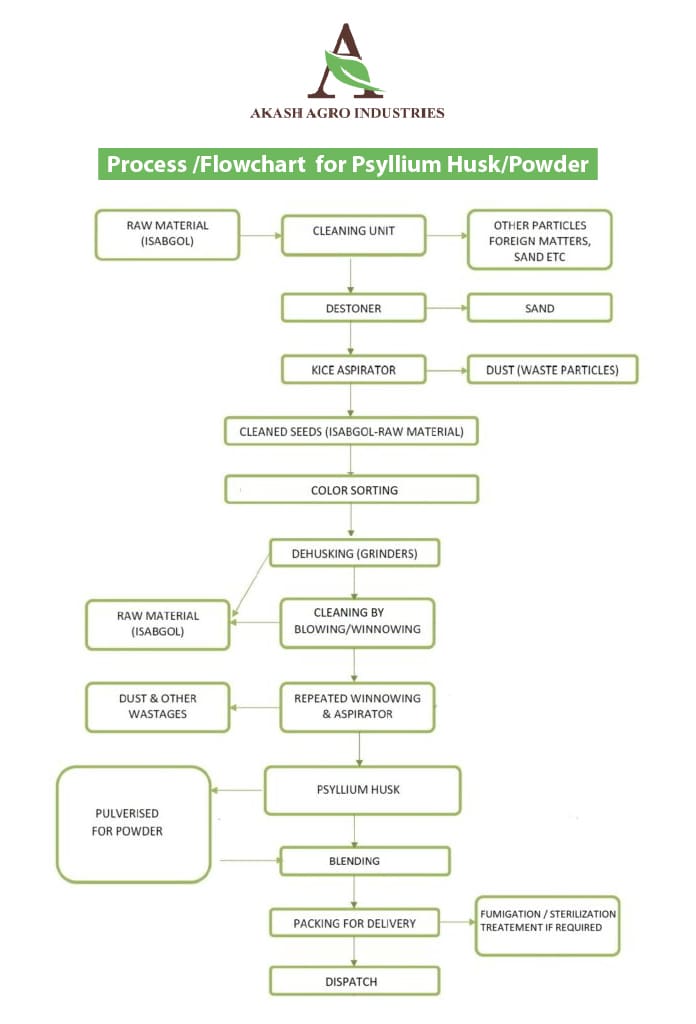

The first step in our processing journey is the thorough cleaning of raw psyllium seeds. Using advanced mechanical processes, we ensure that no chemicals are involved, maintaining the organic integrity of the seeds. Our rigorous ten-stage cleaning process can handle up to 500 kg of psyllium seeds per hour. This comprehensive cleaning ensures that all impurities are removed, setting the stage for the next critical phase.

De-husking is a vital step in obtaining high yields of pure and quality psyllium husk. The process involves milling intact psyllium seeds in specialized mills that cause the husk to be fragmented through collision. This technique ensures that the husk is separated from the non-husk portion of the seed without significant breakage or size reduction of the latter. Our de-husking system features automatic feeding and operates two parallel plants equipped with 72 grinders, each with a 36-inch diameter. This setup allows us to produce 200 kg of de-husked materials per hour.

Following de-husking, the psyllium husk undergoes further purification through a process known as winnowing. Gravity separators are used to ensure that the husk is thoroughly cleaned and free from any remaining impurities. This step is crucial for achieving the high purity standards required by our customers.

To ensure the highest quality and safety of our products, our plant is equipped with a fumigation chamber designed according to expert specifications. The fumigation process involves treating both raw psyllium seeds and the final products with appropriate dosages of fumigants. This step is carried out as per the specific requirements of the importing country and our customers, ensuring that the products are free from pests and contaminants.

For customers requiring additional safety measures, we offer sterilization treatments using Ethylene Oxide, Methyl Bromide, and Gamma Rays Irradiation. These treatments are provided through contract facilities and are conducted upon specific requests from our customers. Sterilization ensures that the psyllium products are free from any microbial contamination, making them safe for consumption and use in various applications.

At Akash Agro Industries, we prioritize delivering our premium processed psyllium in flexible and cost-effective packaging solutions. Our packaging options include Super Sacks, Paper Bags, PP Woven Bags, and Fiber Drums. We ensure that all packaging is done under stringent hygienic conditions to keep the product safe during transit and storage. Our goal is to provide packaging that meets the diverse needs of our global customers.

Quality control is a cornerstone of our operations. Our in-house laboratory is equipped to conduct a wide range of tests, including microbiological assessments, to ensure that our products meet the highest standards. By maintaining rigorous quality checks, we guarantee that our psyllium products comply with the specifications of our buyers, ensuring consistent quality and reliability.

Maintaining a clean and hygienic processing environment is paramount at Akash Agro Industries. Our plant undergoes weekly and fortnightly cleaning routines, including inner and outer spraying, fogging, and placing rodent traps. We keep detailed records of these activities in logbooks. Additionally, our fumigation agent, Excellent Pest Control, provides regular guidance to ensure that our sanitation practices are up to date and effective.

Conclusion At Akash Agro Industries, our commitment to quality, hygiene, and customer satisfaction is reflected in every step of our psyllium processing journey. From the initial cleaning of seeds to the final packaging, each stage is meticulously designed to produce the finest psyllium products available. As a top manufacturer and exporter of psyllium husk, powder, and related organic products, we are proud to serve customers in the USA, Europe, Italy, and beyond. Our fully automatic, ultra-modern processing plant, combined with our dedication to maintaining a clean and hygienic environment, positions us as a leader in the psyllium industry.